The sailing yacht Hetairos has recently completed a major refit at Pendennis shipyard in the United Kingdom. Originally built in 2011 by Baltic Yards, Hetairos has always been a remarkable vessel, both in design and in performance. With this latest refit, the yacht has been upgraded with modern technology to meet today’s standards for comfort, reliability and efficiency.

Marble Automation was selected to deliver a complete automation package for this project. Our scope included the design, delivery and integration of a wide range of control and monitoring functions, all linked through a central system. The goal was to give the crew and engineers simple, clear and reliable tools to operate the yacht.

Hardware

At the centre of the system are eight PLCs with IO cards and network switches. These form the control backbone of the vessel. To give easy access to information and control, six HMI panels have been installed in key locations. The PLCs are connected in a ring setup, which makes the system robust and ensures continued operation even if one connection is interrupted. The HMIs present all important data in a clear format, so that the crew can quickly see the status of equipment and react if needed.

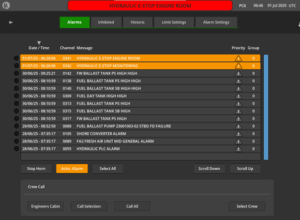

Alarm monitoring and control

A configurable alarm system has been integrated, allowing operators to manage alarms across the vessel. The crew can adapt settings and thresholds to match operational needs. This flexibility helps to create a safer and more reliable environment on board.

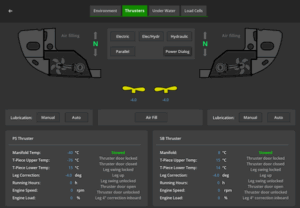

Through the automation system, the full climate installation can be managed. The PLCs control HVAC units, chillers, fan coil units, freezers, fridges, boilers and fans. Equipment from Heinen en Hopman is also included in the system. In addition to climate, the system provides a full overview of the power state of the yacht. Information on oil levels, temperature readings, emergency stops, pumps, hydraulics and frequency drives is displayed clearly on the HMIs. A single line diagram of the power system gives the crew insight into the distribution of power across the yacht.

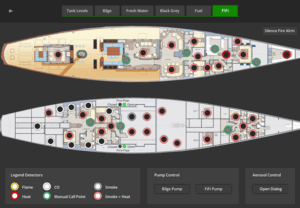

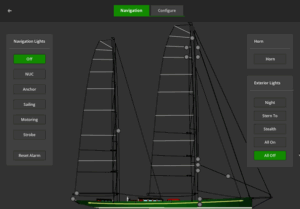

Fire detection and lighting

Safety is supported with an integrated fire detection system. The state of all detectors can be monitored, and the location of any alarm is shown directly in the system. This improves response time and gives the crew confidence in handling emergency situations. Control of both navigation lights and interior lights is also included. With this, all lighting can be operated from the same central system, which simplifies operation.

Sailing and navigation

For sailing operations, a dedicated sailing section has been developed. This gives a complete picture of the vessel’s state. Data from Pixel-sur-Mer is integrated, showing current coordinates, conning information, depth, rudder angle, keel position and bowthruster status. Additional data includes chain counter, propeller state, and detailed sail information. By combining this information in one place, the system helps the crew to manage the vessel in an efficient and organised way.

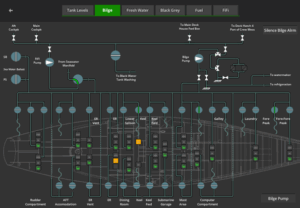

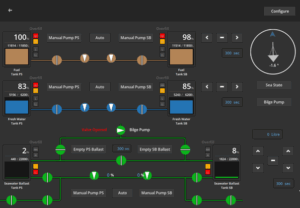

Tank control and bilges

Levels of all tanks are displayed, giving the crew direct insight into fuel, fresh water, black and grey water and other consumables. A custom ballast and bilge system has also been delivered. This system separates bilge, fresh water, black and grey water and fuel handling. Dividing these functions makes operation simpler and provides a clear structure for monitoring.

Network and data storage

The automation system includes a network overview which displays all connected devices. This makes it easy to identify any problem in the network and to see the status of PLCs and IO. Marble Pulse is included to store operational data for more than a year. This long-term data storage allows the crew to analyse past performance, detect patterns and use the information for maintenance planning or troubleshooting.

Integration and reliability

By combining all these functions into one central automation package, the refit of Hetairos ensures that the yacht is ready for future use. The robust ring setup of the PLCs, together with the clear HMI panels, gives reliability and transparency. The integration of safety, climate, power, sailing and network information provides the crew with a complete set of tools to manage the yacht effectively.

A refit for the future

The original build of Hetairos at Baltic Yards in 2011 resulted in a yacht that stood out for its size and performance. The refit at Pendennis shipyard has now added modern systems and technology, ensuring that the yacht continues to meet the demands of luxury sailing today. Marble Automation is pleased to have contributed to this project with a complete automation solution that combines proven technology with tailored design.

With this package in place, Hetairos is well prepared for years of safe and comfortable sailing.