For the shipping company Rederij Doeksen, Marble Automation and Piet Brouwer

Elektrotechniek have successfully developed and installed a modern DC Power

Management System on board the ferry Willem de Vlamingh.

Elektrotechniek have successfully developed and installed a modern DC Power

Management System on board the ferry Willem de Vlamingh.

As part of this upgrade, a 900 kWh battery pack was added. This gives the ship the power

flexibility needed for more efficient and cleaner operations. Two Randax Permanent Magnet

(PM) electric motors were installed by Piet Brouwer to work alongside the existing LNG

engines. During the refit, the ship was also upgraded with six bow thrusters, improving

manoeuvrability.

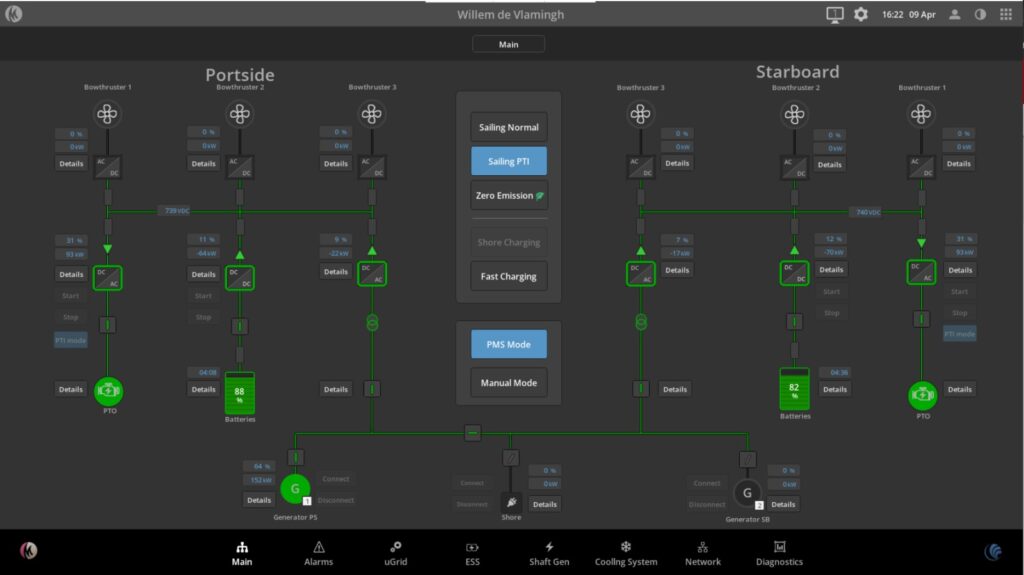

The DC Power management system of Marble Automation ensured that all systems could

work together smoothly and reliably. To make the full system easy to monitor and control, we

added five HMI screens: one on the bridge, two on each ship side, one in the DC room, and

one in the control room. This way, the crew always has a clear and direct view of the

system’s performance.

Additionally, we programmed a dedicated cooling system, using IO-Link sensors to monitor

and control temperature-critical components with high accuracy and flexibility.

The full integration of the DC Power system ensures that all power consumers on board –

whether engines, AC grid, or bow thrusters – receive stable and sufficient energy for safe

and smooth sailing.

To complete the system, we integrated everything with the existing alarm and monitoring

systems, securing safe operations and a reliable power overview at all times.

Lower fuel consumption

With all these improvements and the PTI/PTO (Power Take In / Power Take off) capabilities

of the new PM engines, the Willem de Vlamingh now uses significantly less gas, making the

ferry both greener and more economical.

of the new PM engines, the Willem de Vlamingh now uses significantly less gas, making the

ferry both greener and more economical.

This successful project was a great collaboration with several strong partners, including

Werft Shipbuilding, who managed the full refit process.

Werft Shipbuilding, who managed the full refit process.

Ready for a green future

Thanks to the new DC system and hybrid upgrade, the Willem de Vlamingh is now ready for

a cleaner and more sustainable future.

a cleaner and more sustainable future.

And we’re not done yet – in early 2026, sister ship Willem Barentsz will also receive this

hybrid upgrade. Marble Automation will again support this project with our expertise in

automation and power management.